TIMBER QUALITY LAB TESTING

Our lab is IAS Accredited & American Lumber Standards Committee approved

YOU NEED TO BE SURE THE STRUCTURES YOU’RE relying ON CAN BE TRUSTED.

Assessing wood strength, density, buoyancy, species identification, and more.

If you’re curious or concerned about it, we can test it.

“What kind of wood is this?” “Is there decay in my structure?”

“How old is this wood?” “Can these beams support my structure?”

SMALL-SCALE STRENGTH TESTING

We test the strength of all wood samples, using a Tinnius Olsen Testing Machine. Starting with light pressure, the machine pushes against the wood, slowly raising the pressure to assess its strength.

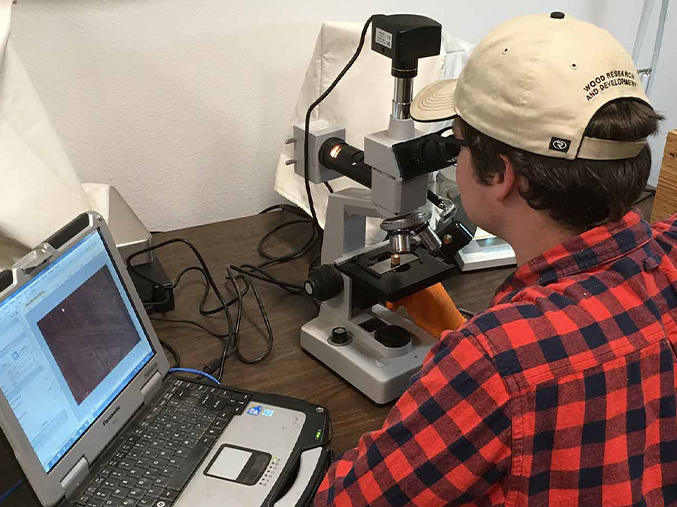

Wood Species identification

By looking at timber samples on a cellular level, we can identify the species and health of the wood. This information informs a highly-specific restoration plan.

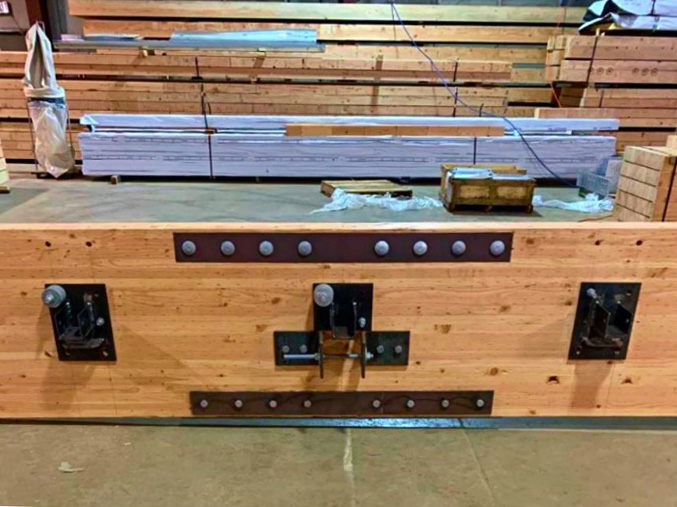

large-scale strength testing

Big Blue, our large beam testing machine, was featured on the History Channel’s “How it’s made.” We use it to test our glue-laminated beams, which are layered with Kevlar. Yes, that Kevlar. It’s the same material used to make bulletproof vests.

IAS Accredited Labs Services

Our engineers and labs are at your service. WRD features labs that have been IAS accredited for over 30 years. We don’t just test wood strength; we also research wood density, buoyancy, and much more. Wood Research and Development specializes in wood testing, wood species analysis, as well as new product testing and development.

Our lab is accredited through International Accreditation Services (IAS). Regular internal audits are conducted as well as external audits through IAS in order to maintain our accreditation. These tests cover quality control procedures for every part of lab operations; from staff training, equipment settings, and proper reports.

WRD lab locations produce correct, consistent, and trusted results for our clients by following these policies. Along with small-scale testing of wood specimens, our IAS-accredited lab is able to conduct static tests on full-size structure parts and beams. The static tests allow us to gain a more accurate picture of the physical properties of glue-laminated timber and other composite wood products.