Timber is among the oldest materials used in bridge construction, and is still widely used today, especially for short and medium span bridges. The high strength and the lighter weight of timber make it a desirable material for bridge construction and it remains a cost competitive option when compared to other material choices. However, in the 20th century, the use of timber has largely been displaced by steel and concrete, and there is a perception among many bridge designers and highway officials that timber is no longer a viable option for large-scale highway bridge projects. We will discuss 6 Reasons to consider using timber, instead of going with concrete and steel, when restoring or replacing your structure. But before anything…

Here’s a fun question for you:

If a structure is still 80-90% good, the question is why would we tear it down? If any of you had a car or house that was 80-90% good, would you do the same? Most likely not. So why is it that when it comes to structural things, some of us think that way?

What experts do, is find the weakest link in the structure. Because if we can get to the “weakest link” on the structure, it can be repaired, and ultimately saved. After the project is complete, 100% of the time, the structure’s load will be rated higher than it was originally intended.

In 2020, there are a few reasons why organizations and some governments are looking at restoring or even choosing to build timber structures.

Cost savings at construction

Timber structures often have an advantage of steel and concrete structures base on initial construction costs. This is largely due to the lower self-weight and faster installation. Additionally, material costs for the timber restoration is usually competitive with steel or concrete even before accounting for substructure and installation savings.

These advantages can be improved when designers and builders are more familiar with timber. It has been shown that contractors who are unfamiliar with timber tend to give higher bids for timber projects, compared to contractors that specialize in timber. (Moses, et al., 2017)

In a case of a rail bridge restoration project that was done in Georgia, a technician figures out where the “weakest links” would be on the structure. Some engineers would advise to destroy the whole thing. But if done correctly restored and reinforced the weakest points, and the whole project cost about $12,000, as opposed to over $135,000 and 4 weeks in time.

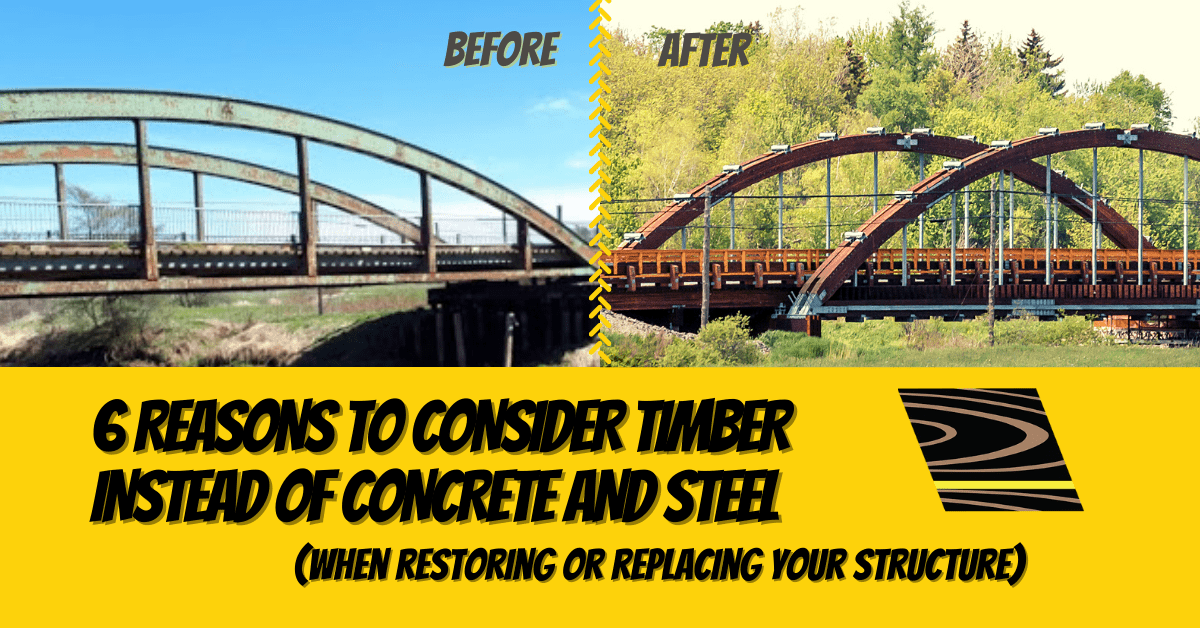

Before and after of a bridge in Nappan, Nova Scotia, Canada. Now known as the Roger Bacon Bridge.

Carbon and environmentally friendly

Timber does not require a great deal of energy for it to be produced into a usable form, relative to other materials such as steel, which require furnaces operating at high temperatures as part of the process.

The manufacturing, transporting, and installation of building materials such as steel and concrete require a vast amount of energy. The small amount of carbon in a ton of concrete, when multiplied by the huge amount of concrete used, results in concrete being the material that contains the greatest amount of carbon in the world; especially because cement production is extremely energy and fossil fuel intensive, making it a large producer of carbon dioxide emissions contributing to global warming.

Ease of construction

Timber is light compared to other building materials, such as concrete and steel. The density of different species of wood varies can vary between 550 kg/m3 and 700 kg/m3, while concrete and steel has densities of about 2,400 kg/m3 and 7,700 kg/m3.

When using timber as a construction material, it allows design flexibility. It’s a very versatile product, with endless possibilites. Whether you’re building a large mass timber project, or framing a house, it’s relatively simple to work with. The most basic project such as making a frame, a small child can learn how to do this with simple hand tools.

Reduced cost of maintenance (compared to steel and concrete)

While it is easy to compare the initial construction cost of various material options, it is more difficult to predict the long term maintenance costs. Engineers and transportation officials are often less familiar with timber than with other materials, and there is a tendency to underestimate the lifespan and overestimate the maintenance costs for timber bridges. A 2006 study found that the maintenance cost for properly protected timber bridges is substantially lower than typically estimated (Gerold, 2006). The study evaluated over 50 modern various bridges in Germany and calculated the annual maintenance costs as a percentage of initial construction costs. Among the bridges tested, the annual maintenance costs varied from 0.1% to 2.5% of the initial construction costs. Gerold concludes that the service life and maintenance costs of timber bridges are comparable to those of steel and concrete structures. He suggests that an appropriately conservative estimate for road bridges would be 80 year service life and annual maintenance costs of 1.3% of construction costs.

Silica Contamination (when using concrete)

Silica is an extremely toxic chemical in the world. If you cut concrete with a saw, you have to have a urine test once a week to test for poisoning. According to the OSHA in the US, “Inhaling very small (“respirable”) crystalline silica particles, causes multiple diseases, including silicosis, an incurable lung disease that can lead to disability and death. Respirable crystalline silica also causes lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease.”

In many countries, to build a concrete bridge over a reservoir is no longer allowed for public safety.

Longevity

We say timber doesn’t last. That’s the mantra. People often compare timber bridges that are hundreds of years old against reinforced concrete bridges that are 40 years old and say, “concrete lasts so much longer.” These old timber bridges have been giving great service for three and four times longer than the concrete bridges with poor maintenance practices and little, or no upkeep! If we treated concrete bridges the way we treat the timber bridges, who knows how short their life would be. Interesting as well that the old timber bridges that have been lasting so long were designed for significantly lower loads, yet they have continued on in service carrying much higher loads than they were built to carry. If we overloaded concrete bridges the way we overload the old timber bridges, the concrete bridges longevity would be considerably shorter than what it is now.

There you have it. These are the reasons why timber structures need to be restored, and not torn down. For a lot of organizations, it could sum up to cost. Nowadays, budget is important, and if there’s an opportunity to save some money, timber is the way to go. For those who take the environment to heart, restoring your timber structure is a lot safer than going with steel and concrete. When using timber as your main construction material, just know that it will be so much easier, with less maintenance too. When it comes to long-term health, hands down timber is better than the conventional steel and concrete.

There is something magical about a wooden structure. The feeling of amazement that embodies everyone around, just admiring the beauty. Which matter to you the most? If you have a wooden structure that you may need help with, or know of one that is in need of restoring, please contact us, we’d be more than happy to discuss!

References:

Gerold, M. (2006). Economic Viability of Modern Timber Bridges – Lifespan and Costs of Maintenance. IABSE Reports, 92, p. 384. Budapest.

Moses, D., Alexander, M., McAlister, K., Mesa, K., Lehan, A., Brown, S., & Dulay, G. (2017). Ontario Wood Bridge Reference Guide. North Bay, ON: Ontario Wood WORKS.